The PLASTIC Business Unit (BU) has the main technologies for the manufatcuring/production of thermoplastic materials. Thanks to injection molding technology and the available press fleet, this BU is able to produce medium and large components, using all the polymers (from polyethylene to polypropylene up to technopolymers, such as polyamide and polycarbonate).

Blow molding technology allows the production of components, even large ones, mainly using polyethylene and polypropylene, such as snorkel for trucks, fuel tanks and air intake ducts. The bimaterial 3D blow molding allows the production of ducts with complex shapes and with the simultaneous use of different materials (polypropylene and santoprene, rigid and soft nylon, hytrel and crastin, fiberglass polypropylene).

This technology, recently developed and of which Cornaglia is among the European leaders, has allowed the replacement of rubber parts inside engine compartments, with substantial savings in terms of costs and weight, an important improvement in quality / performance, allowing the complete recyclability of the product.

The bimaterial 3D blow molding is today establishing itself as a valid alternative to stretched and silicon rubber ducts. The rotational molding technology allows the production of complex and large parts such as cab roofs, tanks, fenders and interior components, mainly for the market of industrial vehicles and agricultural and construction machines.

The twenty-year experience in the production of technical rotomolding parts means that they are particular parts painted (or intended to painting), also in technopolymers. As for the assembly, the produced components can be welded using different technologies (hot blade, ultrasonic, vibration, roto friction) and processed on robotized finishing and assembly areas.

Products

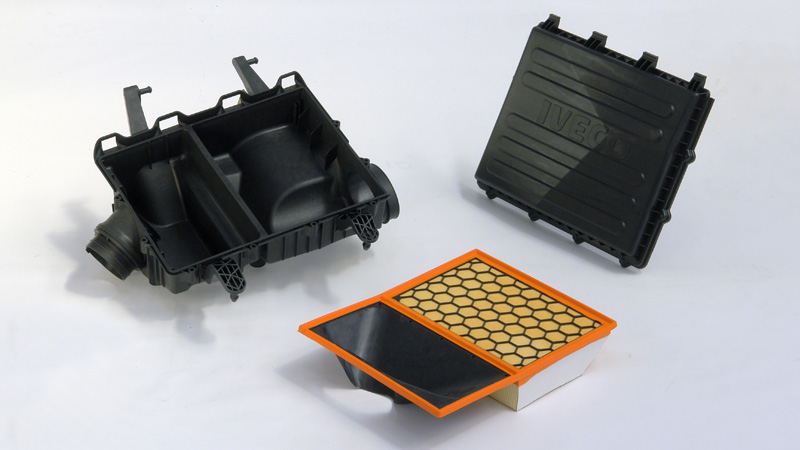

- Airboxes

- Engine air ducts

- Hvac ducts

- Snorkel

- Pressure duct

- Fuel tank

- Urea tank

- Oil tank

- Water tank

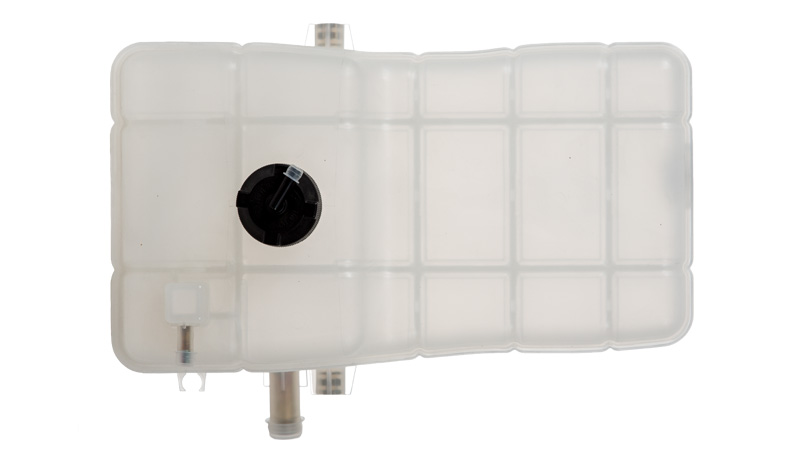

- Expansion tank

- Heated Blow By

- Shelding

- Sender

- Roof

- Exterior cabin components

- Interior cabin components