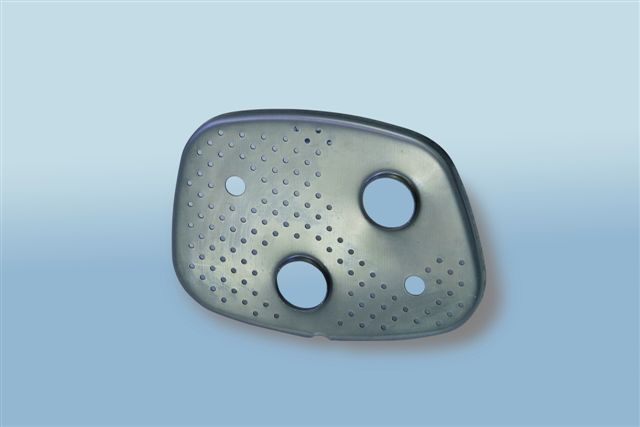

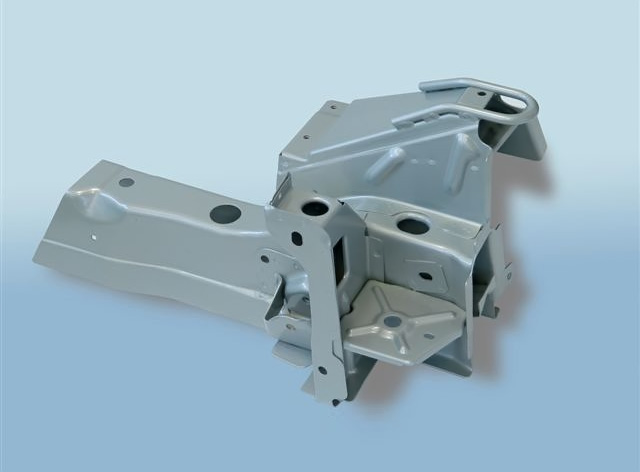

The METAL Business Unit (BU) performs stamping of medium and large components, with thicknesses from 0.6 to 8 mm, and of different types of materials, such as sheet metal, high resistance sheet, Antiphon, stainless steel and aluminum.

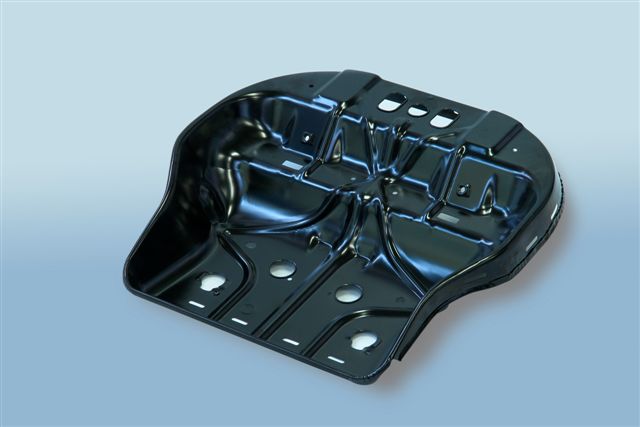

An important feature is the stamping of components that require deep drawing, such as the truck oil sump.

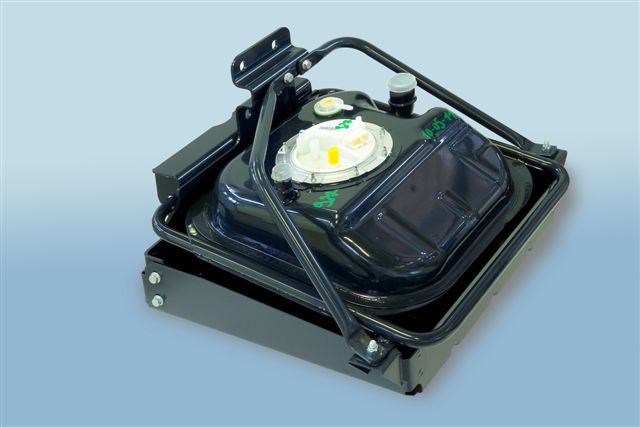

The components are assembled with all of the welding technologies (wire welding, spot welding, projection, braze welding in an oven with controlled atmosphere) and they can be painted with cataphoresis and powder coating processes, with the possibility of choices of different colors.

Products

- Fuel tank

- Oil sump

- Details for cat body (brackets, wheel compartments, etc.)

- Aluminum components for hybrid vehicles

- Foundry seats